Description of products

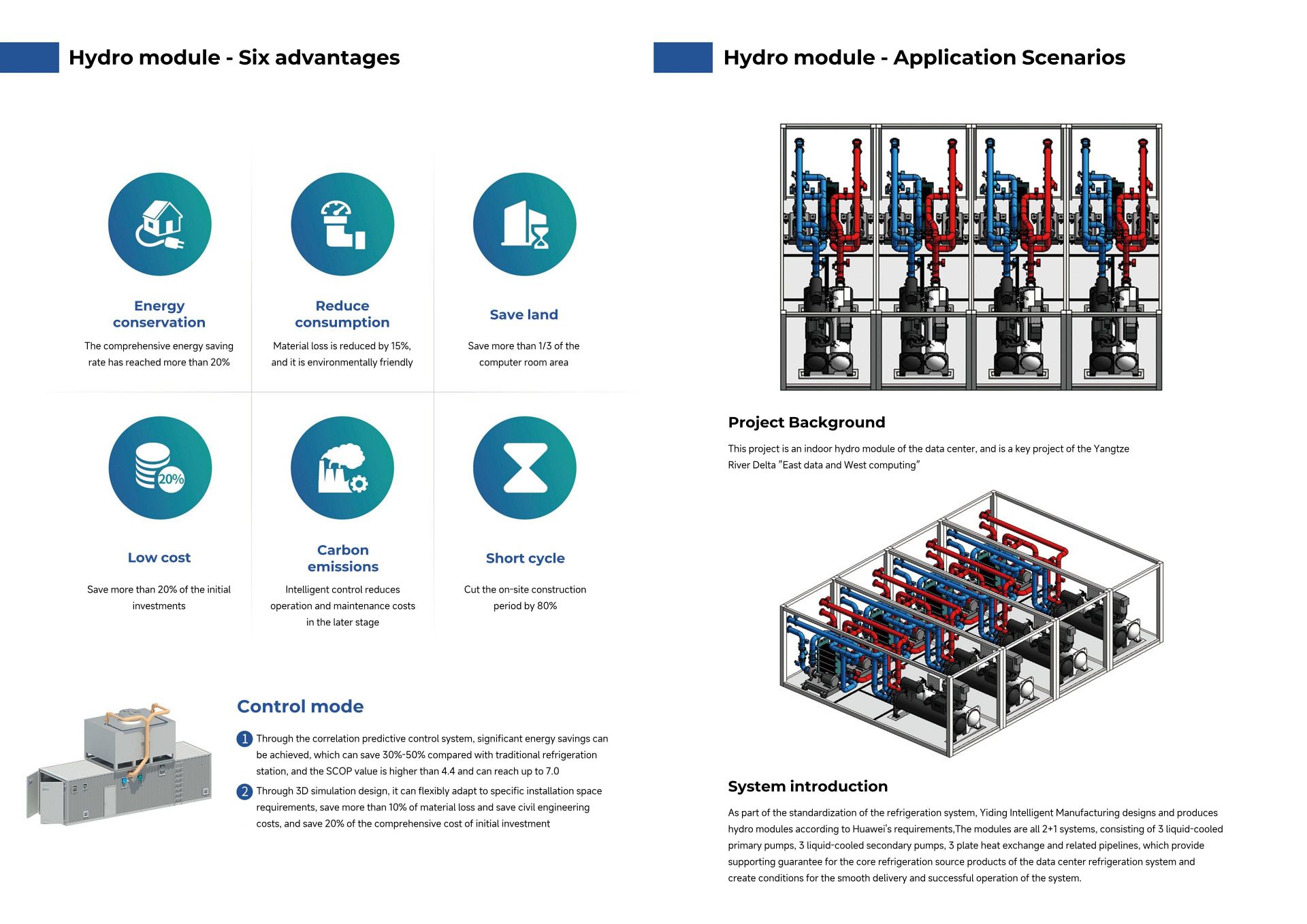

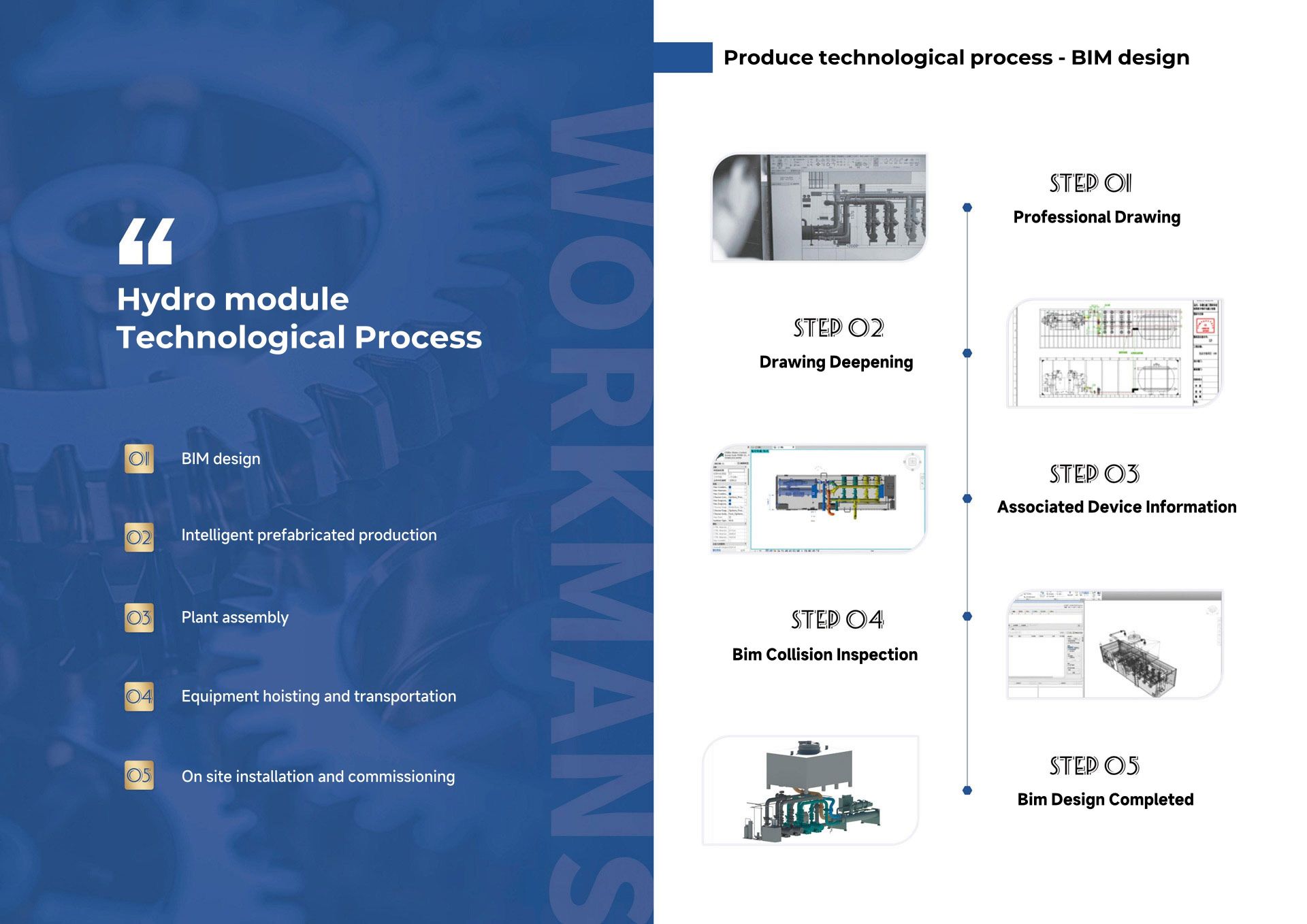

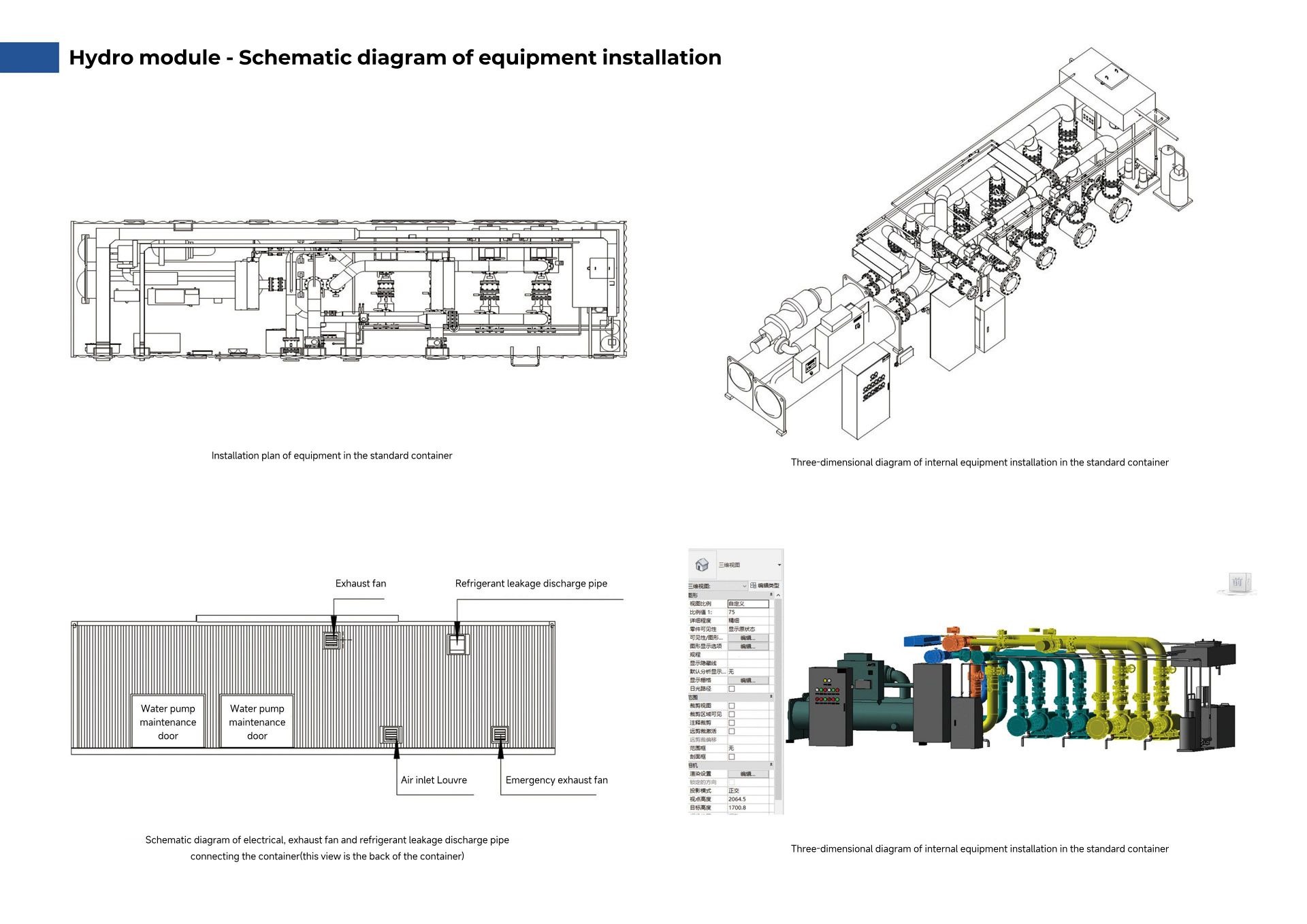

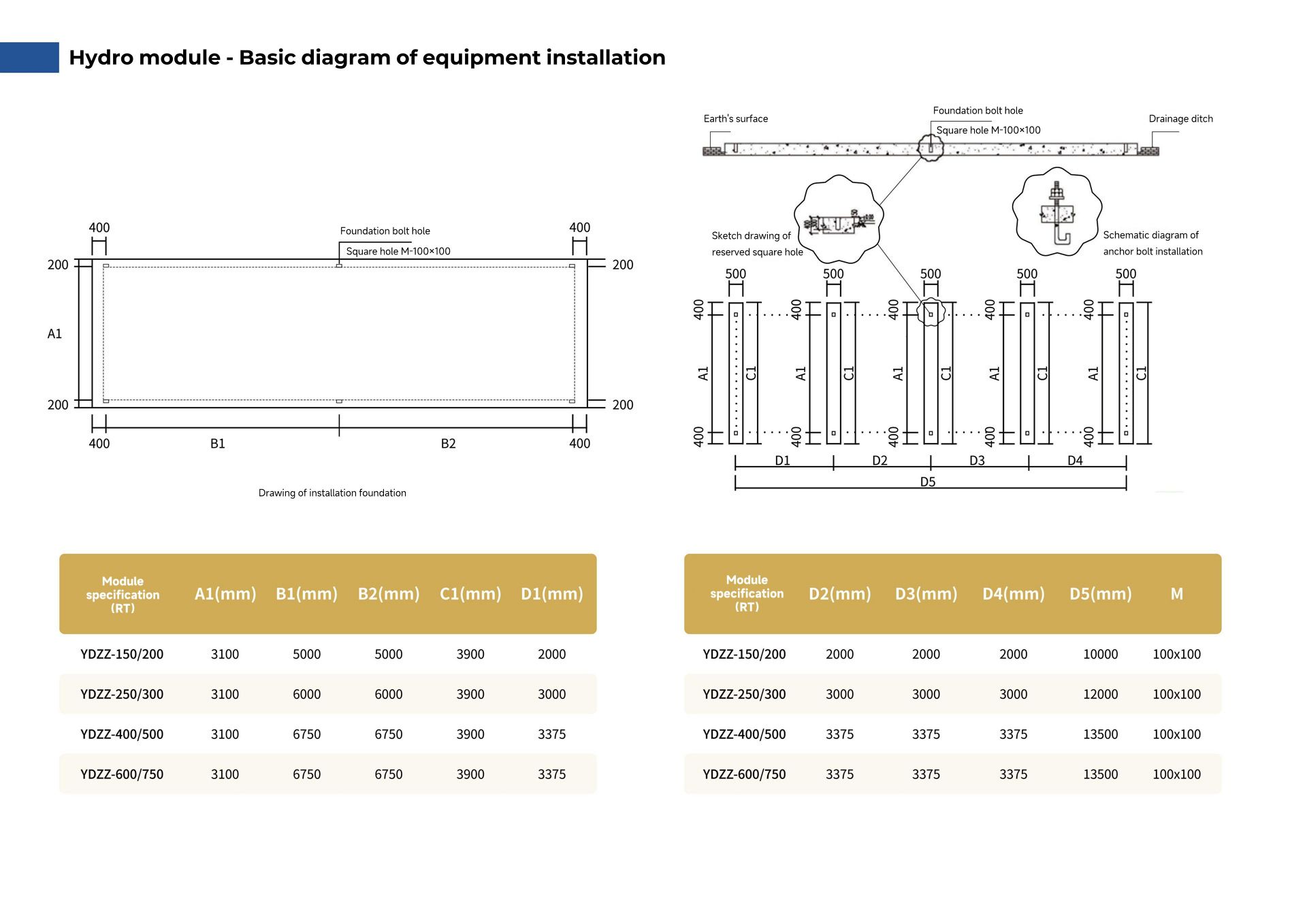

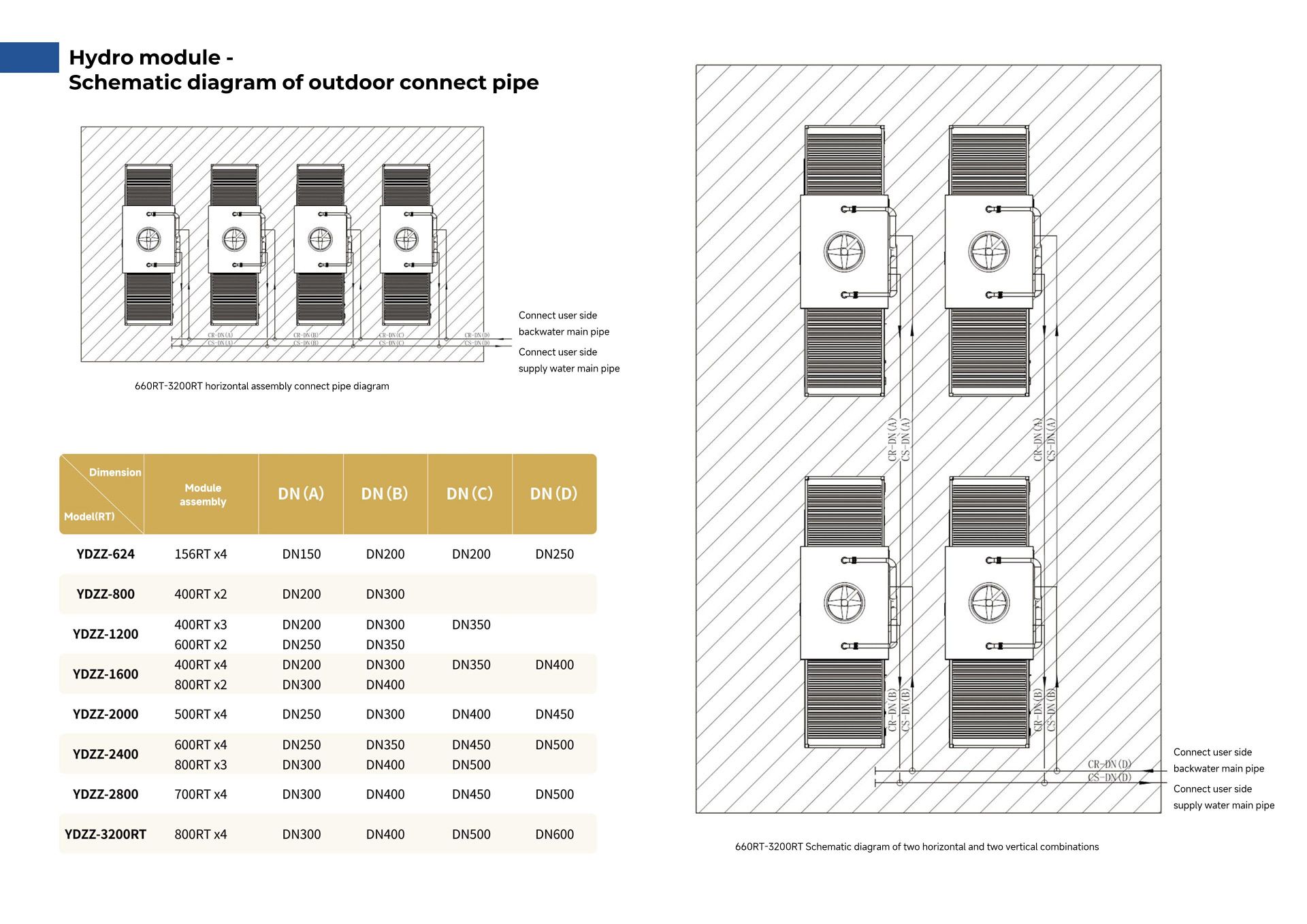

1. According to customer needs, combined with the actual situation of the project site customization, BIM design modeling, pipeline optimization.

2. The self-contained pump skid is equipped with variable frequency water pump, and the standby pump is set to automatically adjust the water flow according to the actual demand. The state of the water pump is controlled by the self-control signal of the unit.

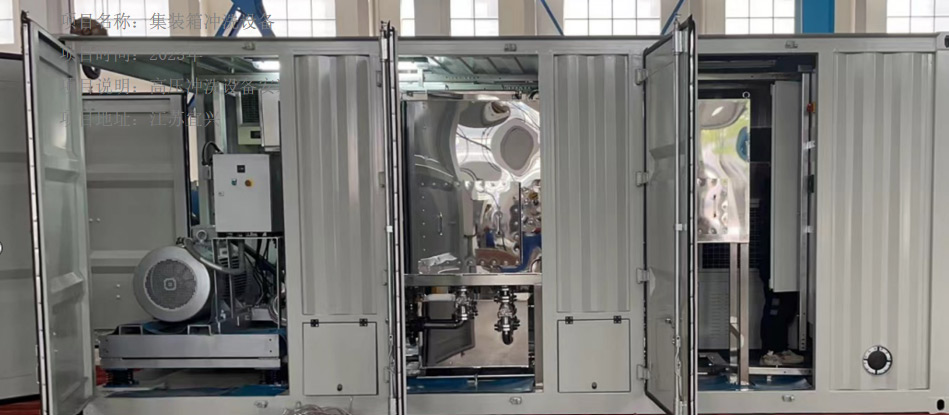

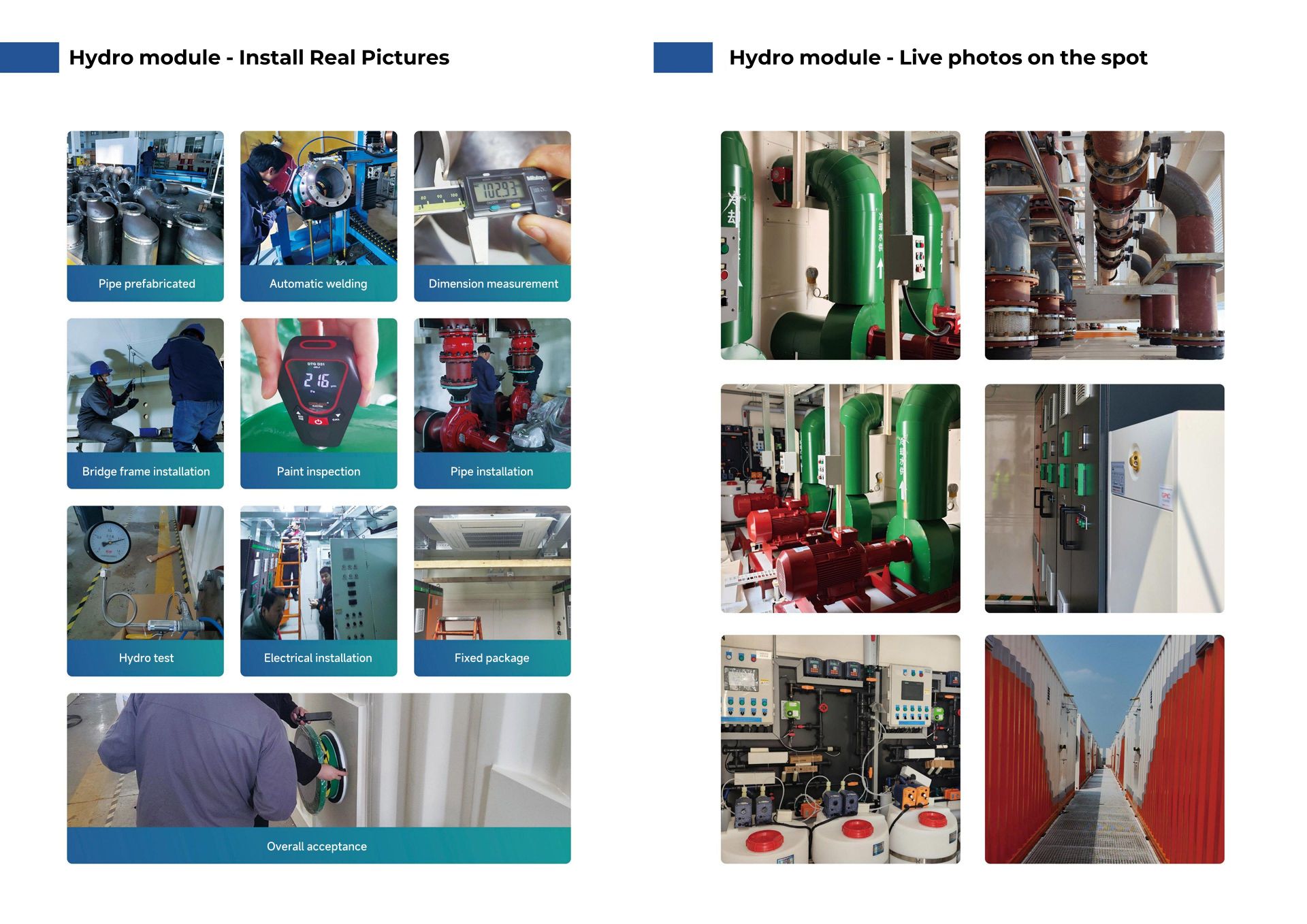

3. Through factory prefabrication, assembly and debugging of various operating conditions of simulation adaptation projects, the safe operation of modules, one-button start-stop and unattended operation are realized.

4. After factory inspection, the equipment can be put into operation after being transported to the project site and connected with hydropower.

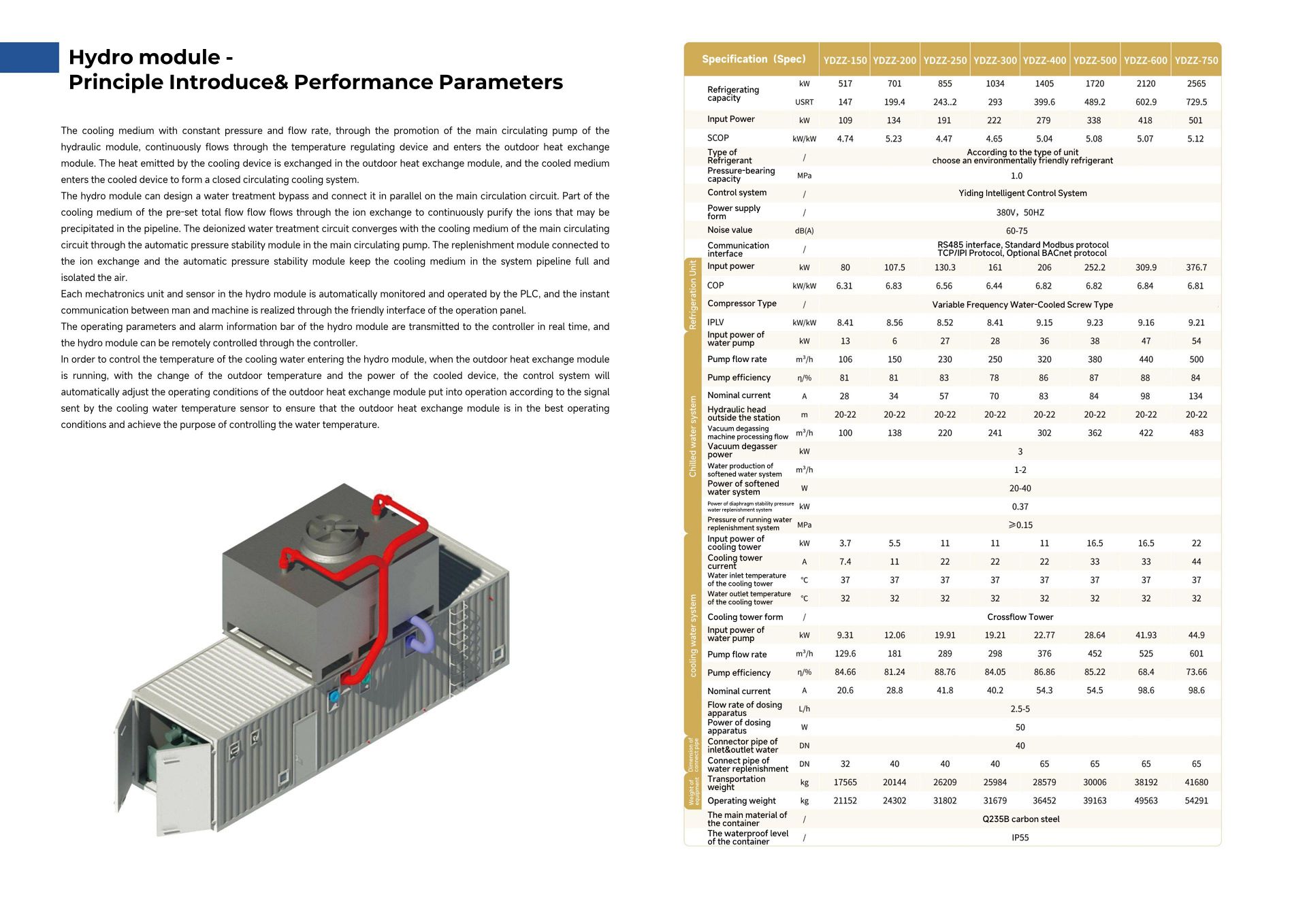

The water cooling module shall improve the energy efficiency of the system through performance-based design, fine construction, system commissioning and monitoring, energy-saving optimization operation and other measures according to the local climatic conditions and building functions on the premise of meeting the cooling demand. The selection parameters and control logic of the air conditioning terminal equipment shall match the system design scheme of the cold source of the water cooling module.

On the premise of meeting the terminal demand, we can comprehensively consider the load matching degree, system energy rationality and other factors, apply high-performance equipment, use scientific control mode and management system, reasonably control each equipment in the system, adjust the system operating parameters, so as to realize the system high energy efficiency operation.

The device can be used for centralized cooling of air conditioning in factory buildings, office places and temporary emergency places in summer.

Data Centre

DC in Chinese is the homonym of AIE-Station, which also represents the wider application field of artificial intelligence in the era of big data, and also expresses the execution force of perfectly completing intelligent energy station, namely, fast response speed (factory prefabricated production, on-time delivery, simple on-site construction), long life cycle (overall movable, can be used for many times and on many occasions), and love for use (unattended, safe and reliable operation, quality & appearance worthy of customer expectation).

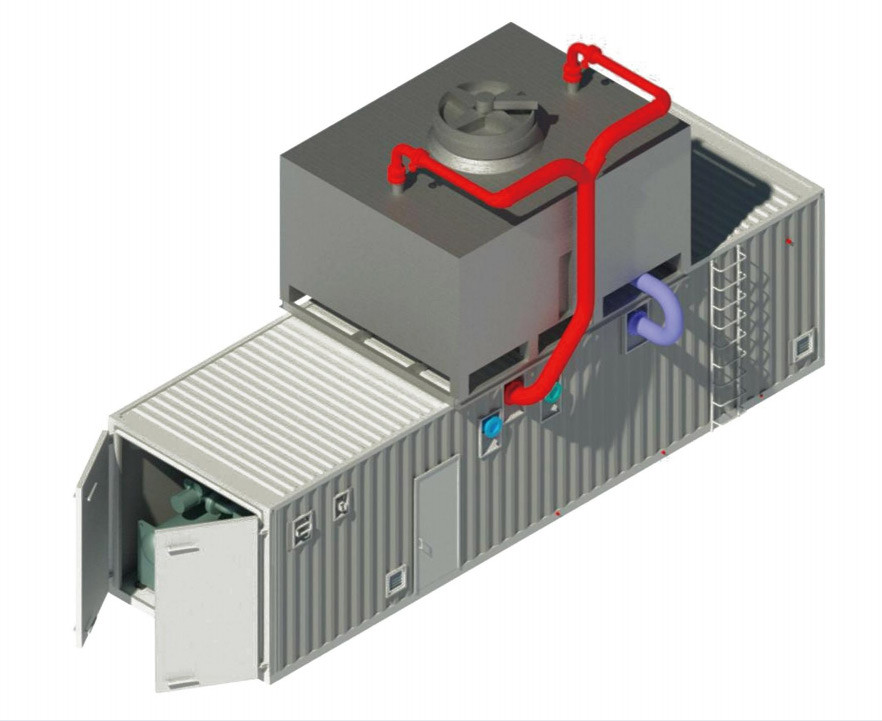

DC (data centre) is to complete the overall assembly of pipelines, valves, pump bodies and refrigeration hosts and the prefabricated processing of cabin bodies in the factory, so as to finally become modular customized products. Its appearance condenses the energy of the times. It realizes modularization, systematization, intellectualization, mobility and repeated use of civil central air conditioning room, and initiates a new era of ventilation and air conditioning industry.

Product Notes

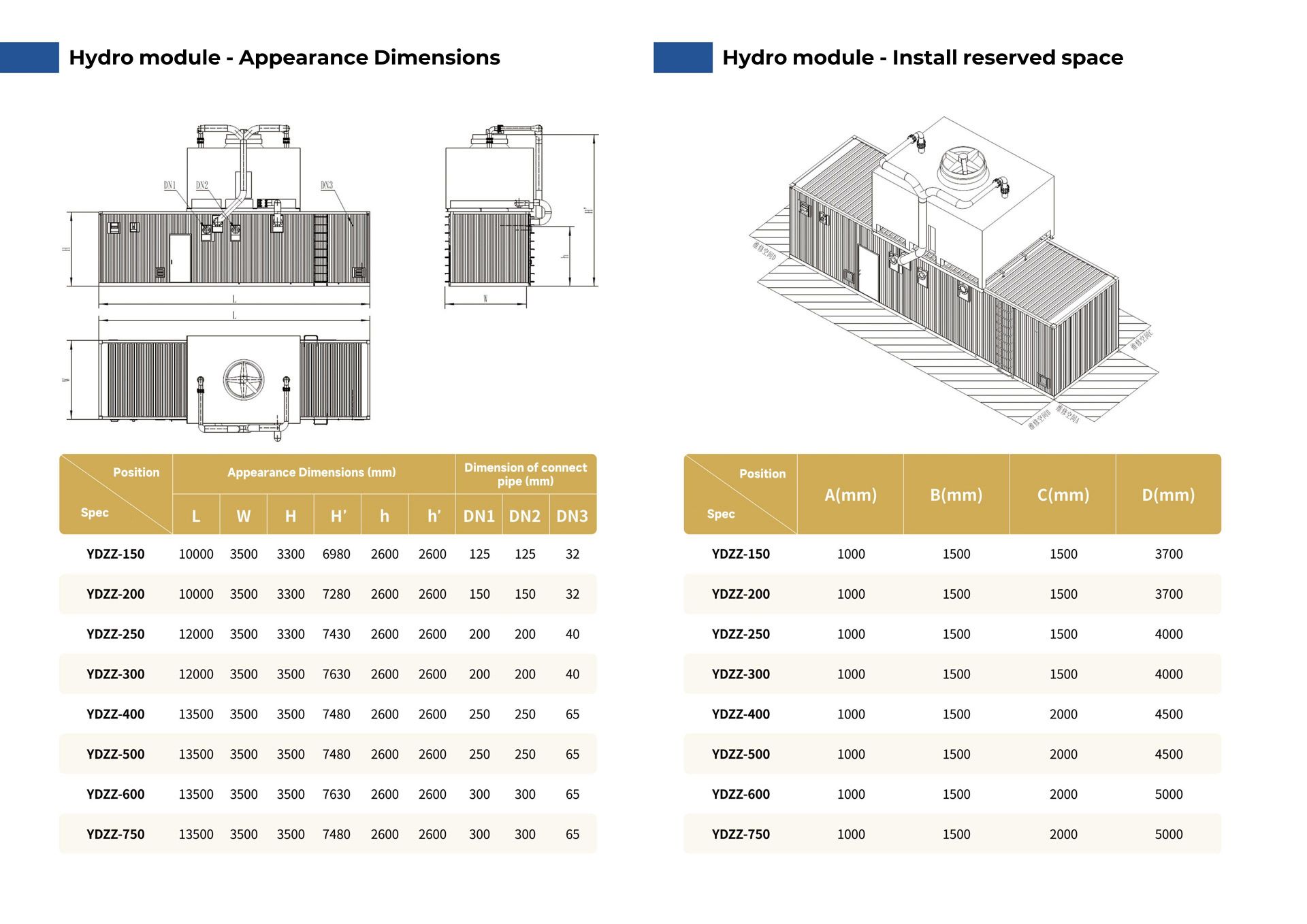

1. BIM software can be used to customize the size and optimize the pipeline according to customer requirements.

2. The modular water-cooled prefabricated cabin integrates water-cooling unit, variable frequency water pump, water treatment device and electrical control equipment. The system automatically adjusts water flow according to actual operating conditions and stable output cold capacity. The prefabricated cabin has its own control system for automatic adjustment.

3. Through the factory's overall prefabrication, assembly and field debugging of each operating condition of the simulation adaptation project, the safe, stable and reliable operation of the module, one-button start-stop and unattended operation are realized.

4. After factory inspection, the prefabricated cabin as a whole can be used after being transported to the site and connected with water and electricity.

Integrated cold station is a refrigeration station that can be moved conveniently. Its system consists of refrigeration system, water circulation system, throttle mechanism and air circulation system. Operating mechanism: In the vapor compression refrigeration cycle system, the compressor sucks refrigerant vapor with low temperature and low pressure from the evaporator, compresses it into superheated vapor with high temperature and high pressure through the adiabatic compression of the compressor, then presses it into the condenser for constant pressure cooling, and releases heat to the cooling medium, and then cools it into supercooled liquid refrigerant. The liquid refrigerant becomes low pressure liquid refrigerant through the adiabatic throttling of the expansion valve (or capillary tube), evaporates and absorbs heat in the circulating water (air) of the air conditioner in the evaporator, Thus cooling the air conditioning cycle water (air) to achieve the purpose of refrigeration, low pressure refrigerant out of the suction compressor, so cycle work.

Integrated cold station can be widely used in data center, biochemical medicine, manufacturing and new energy power stations and other fields or places.

Copyright © 2024 Wuxi Yiding Intelligent Manufacturing Technology Co., Ltd. All Rights Reserved.